Optimizing FI at programmable flow

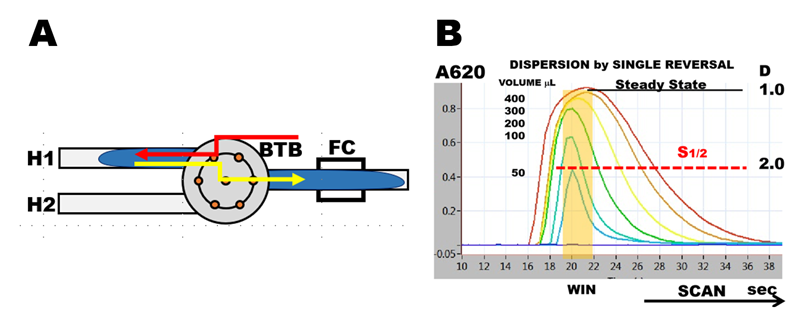

Impact of single flow reversal on dispersion of material into the carrier stream during the passage through the pFI manifold (A) is seen on the shape of F-curve (B) obtained by injection of increasing volumes of a dye and by monitoring absorbance at the exit. In this experiment zone of bromothymol blue (BTB) disperses into colorless carrier stream due laminar flow on the way into holding coil (H1) where it experiences a flow reversal and continues back through the valve and into flow cell (FC). The height of the thus recorded peaks increases with increase of injected sample volume (Sv) until the flow cell is filled with undiluted dye and the steady state is reached.

The F-curves obtained at flow reversal are more symmetrical in comparison with F-curves obtained at forward flow (Fig. 1.5.D), which confirms that single reversal efficiently promotes radial mixing.

The peak height at flow reversal increases (C) in similar fashion as at forward flow (Fig. 1.5.E). Thus, increase of injected sample volume until S1/2 is reached, will increase peak heigh, and sensitivity of determination in linear fashion.

The peak height at flow reversal increases (C) in similar fashion as at forward flow (Fig. 1.5.E). Thus, increase of injected sample volume until S1/2 is reached, will increase peak heigh, and sensitivity of determination in linear fashion.

The tailing edge of revered F-curve will require at least five S1/2 volumes of carrier solution to washout all sample material to prevent carryover. However, flow programming offers a way to increase sampling frequency, by acceleration of flowrate, right after peak height value was recoded.

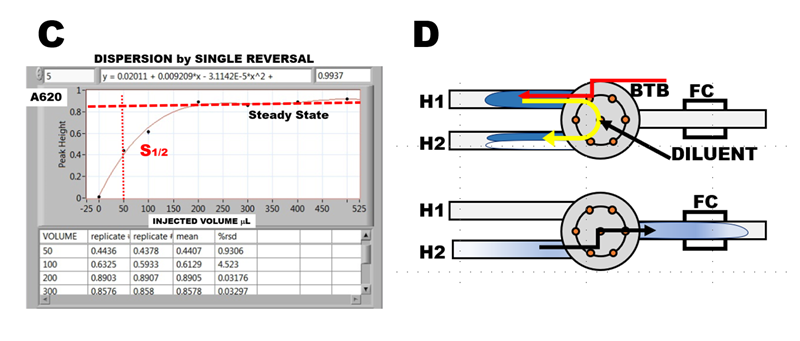

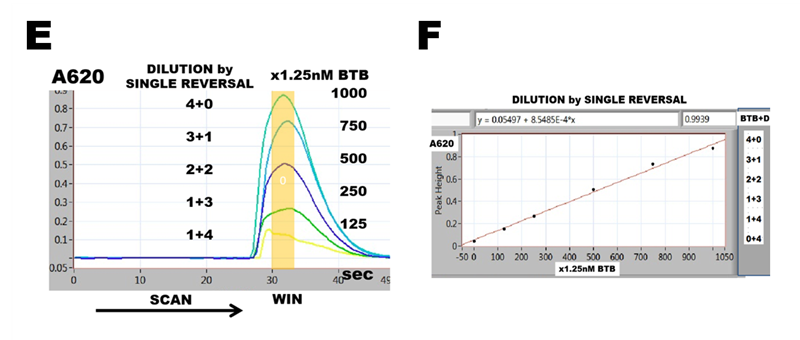

Mixing of dispersed sample zone at confluence point with a stream of reagent is the key operation of all FI protocols. Therefore, stream merging, followed by single flow reversal is presented here in two step protocol (D). In the first step 400 µL of dye (BTB), are aspirated into holding coil (HC1), flow is reversed, and sample zone is merged with diluent, while it is being transferred into HC2. In the second step flow is reversed, and diluted sample zone is moved through the flow cell.

Obviously, it is the ratio of flowrates to which selected volumes are precisely matched, that will yield desired sample/reagent ratio. Thus e.g., to obtain S+R mixture 1+1, 400 µL will be aspirated at a flow rate of 80mcrL/sec into HC2, while 200mcrL of sample zone will be delivered at a flow rate of 40mcrL/sec from H1. By changing dye/diluent volumes from 4+0 to 0+4 a series of near symmetrical peaks was recorded (E), the height of which yield a linear calibration response (F).

Obviously, it is the ratio of flowrates to which selected volumes are precisely matched, that will yield desired sample/reagent ratio. Thus e.g., to obtain S+R mixture 1+1, 400 µL will be aspirated at a flow rate of 80mcrL/sec into HC2, while 200mcrL of sample zone will be delivered at a flow rate of 40mcrL/sec from H1. By changing dye/diluent volumes from 4+0 to 0+4 a series of near symmetrical peaks was recorded (E), the height of which yield a linear calibration response (F).

Stream merging, followed by flow reversal is the cornerstone of all pFI assay protocols. Single standard solution calibration, single line calibration method as well as batch-flow mode of operation are based on precise control of mixing ratios. Also, when sample stream/reagent stream mixing ratio is known, it can be combined with concentration of dispersed sample by using ratio of Sv/S1/2 values. In his way the composition of reaction mixture within the flow cell can be calculated and serve as a valuable guide for optimization of reagent-based assay.

Stream merging, followed by flow reversal is the cornerstone of all pFI assay protocols. Single standard solution calibration, single line calibration method as well as batch-flow mode of operation are based on precise control of mixing ratios. Also, when sample stream/reagent stream mixing ratio is known, it can be combined with concentration of dispersed sample by using ratio of Sv/S1/2 values. In his way the composition of reaction mixture within the flow cell can be calculated and serve as a valuable guide for optimization of reagent-based assay.