3.1.3. Batch - SI format and lab-in-syringe

Let us discuss the difference between batch method and flow-batch method. All manually performed assays are executed in batch format. Sample and reagents, metered into container of well-defined volume, are homogenized, and let to incubate until chemical equilibria are reached (A). For quantification by e.g., by spectrophotometry, solution is transferred into cuvette for absorbance measurement. Thus, measurement is performed on stationary solution of known composition at chemical equilibrium.

The key component of all flow-batch systems is a mixing chamber, preferably well stirred, because its role is to homogenize reaction mixture that may be viscous or comprise immiscible liquids as for solvent extraction. In batch-FI format (Zagatto 2009), sample and reagents move through mixing chamber and through flow cell at continuous flow rate. Therefore measurement is performed on moving solution where chemical equilibrium is not reached.

The key component of all flow-batch systems is a mixing chamber, preferably well stirred, because its role is to homogenize reaction mixture that may be viscous or comprise immiscible liquids as for solvent extraction. In batch-FI format (Zagatto 2009), sample and reagents move through mixing chamber and through flow cell at continuous flow rate. Therefore measurement is performed on moving solution where chemical equilibrium is not reached.

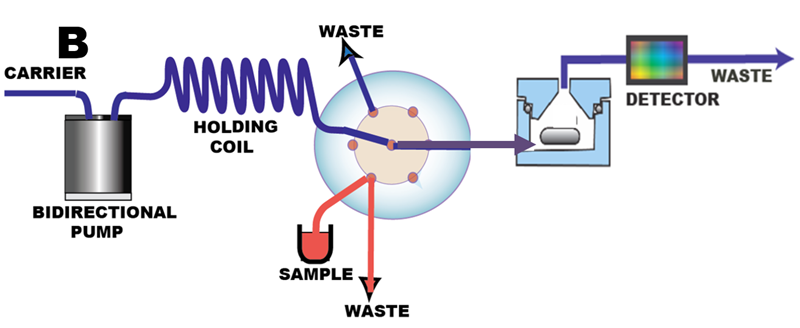

In batch-SI mode (B) versatility of Sequential injection is enhanced because the number of reagents used is no longer limited to two. Also, performance of mixing chamber is enhanced by flow programming. Stopped flow period will prolong incubation time while accelerated flow will rinse the chamber effectively. This is important because the stirred chamber, has typically volume of 1 to 2 mL, which cannot be further reduced, while being more difficult to rinse than systems made of tubular channels. Flow programming lends batch-SI a range of options from kinetic (nonequilibrium ) to static (equilibrium) conditions. While protocols for serial assays will be programmed in kinetic mode, since it yields higher sampling frequency, the static mode that replicates performance of manual batch method can serve as a research tool (Section 3.2.4.)

An example of SI flow-batch method is determination of iodide and iodate in coastal waters by combined spectrophotometry (iodate) and potentiometry (iodide) (Santos 2015). The stirred chamber accommodated iodate/hydrazine/Griess sequence of reactions, which took place during stop flow incubation period at stirring conditions. This innovative design eliminated inability of SI to process more than two reagents. The apparatus comprised 10 position rotary valve interconnecting two peristaltic pumps, two flow cells (potentiometry and spectrophotometry) stirred chamber, and appropriate reagents and standards.

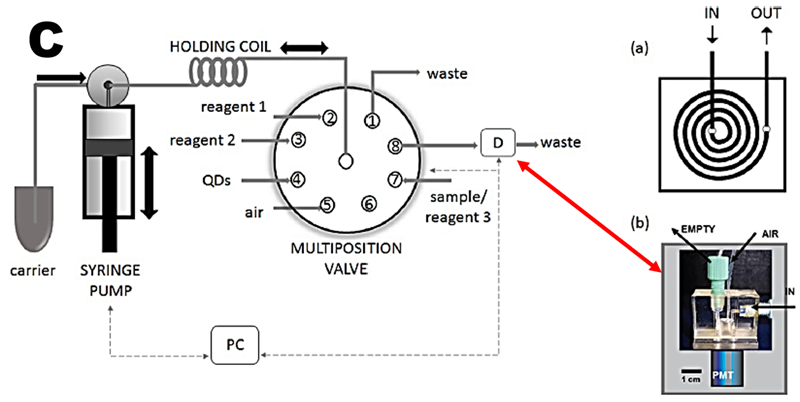

For chemiluminiscence based methods, mixing chamber serves as a flow cell to capture emitted light when reactants are being mixed. The batch type flow cell, coupled to SI manifold (C), was used to investigate enhancement of luminol/peroxide chemiluminescence by quantum dots (Sklenarova 2017).

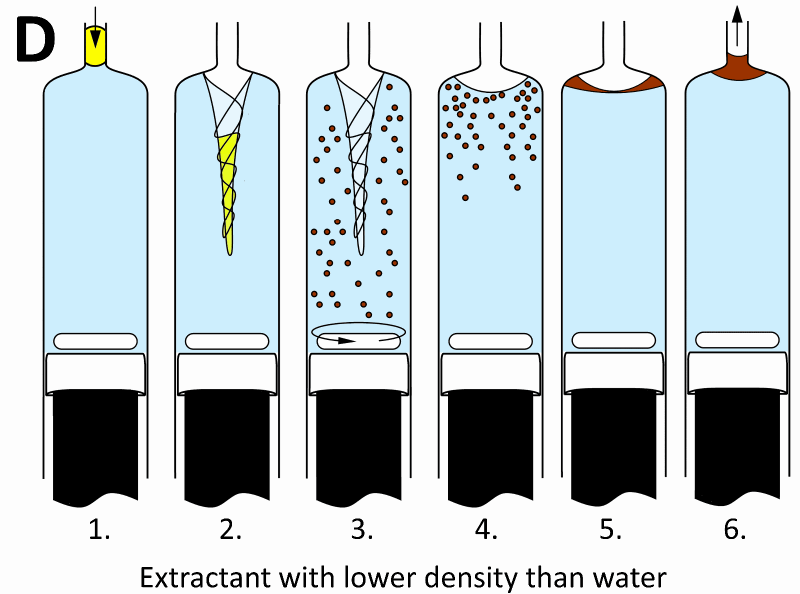

Lab-in-syringe (LIS) is a hybrid of batch-flow concept and Sequential Injection (Maya 2012). It automates metering, mixing and monitoring of sample and reagents at single milliliter scale. It is presently the most efficient method for automation of liquid/liquid extraction and handling of two-phase systems. It can function as “stand alone” analyzer with spectrophotometric detection (Fikarova 2019) with absorbance measured either “in syringe” or in external flow cell. It has been successfully used as “front end”, sample pretreatment module for ICP (Horstkotte 2017 ) and for Gas chromatography (Horstkotte 2018). The most efficient configuration with stirrer bar inside the syringe is shown here in solvent extraction mode (D). (video)

It is out of scope of this writing to review all modalities and applications of LIS developed so far and therefore the recent review by the author of the method is recommended (Horstkotte 2020).

The use of LIS as a tool for research may be worth considering. Since SI-LIS combination can be programmed to replicate conditions of equilibrium batch method, it can be used for determination of distribution ratios of species between aqueous and organic phase as well as for determination of extraction constants of metal chelates (Stary 1964).

Zagatto, E.A.G.; Carneiro, J.M.T.; Vicente, S.; Fortes, P.R.; Santos, J.L.M.; Lima, J.L.F.C. Mixing chambers in flow analysis: A review. J. Anal. Chem. 2009, 64, 524–532.

I. C. Santos, R, B. R. Mesquita, A, A. Bordalo, A. O. S. S. Rangel “ Iodine speciation in coastal and inland bathing waters and seaweeds extracts using a sequential injection standard addition flow-batch method “ Talanta 133 (2015) 7-14.

H. Sklenářová , I. Voráčová, P. Chocholouš, M. Polášek “Quantum dots as chemiluminescence enhancers tested by sequential injection technique: Comparison of flow and flow-batch conditions.” Journal of Luminescence 184 (2017) 235.

Maya, F.; Estela, J. M.; Cerda, V., Completely automated in-syringe dispersive liquid-liquid microextraction using solvents lighter than water Anal. Bioanal. Chem. 2012, 402, 1383-1388

B. Horstkotte, P. Solich “The Automation Technique Lab-In-Syringe: A Practical Guide” Molecules 2020, 25, 12.

K. Fikarova, B. Horstkotte∗, H. Sklenařova, F. Švec, P. Solich “Automated continuous-flow in-syringe dispersive liquid-liquid microextraction of mono-nitrophenols from large sample volumes using a novel approach to multivariate spectral analysis” Talanta 202 (2019) 30.

B. Horstkotte, N. Lopez de los Mozos Atochero, P. Solich “Lab-In-Syringe automation of stirring-assisted room-temperature headspace extraction coupled online to gas chromatography with flame ionization detection for determination of benzene, toluene, ethylbenzene, and xylenes in surface waters”. Journal of Chromatography A 1555 (2018) 1.

B. Horstkotte, K. Fikarová, D. J. Cocovi-Solberg, H. Sklenářová, P. Solich, M, Miró “ Online coupling of fully automatic in-syringe dispersive liquid-liquid microextraction with oxidative back-extraction to inductively coupled plasma spectrometry for sample clean-up in elemental analysis: A proof of concept” Talanta 173 (2017) 7

J. Stary “Solvent extraction of Metal Chelates” Pergamon Press Oxford UK 1964.