Flow programming for batch and equilibrium method

1. Analytical applications

Reagent based assays, automated in Flow Injection format, are based on monitoring of concentration gradient of reacting components, as it passes through the flow cell, while equilibria of chemical reactions have not been reached. This, widely used approach, is feasible and will yield reproducible results as long as the instrument will be calibrated by standard solutions that have similar composition to samples to be analyzed.

However, when calibration obtained with standards prepared in DI water is used to calculate analyte content in samples of different matrix such as seawater, the results will not be correct, because salinity will affect reaction rates, and schlieren effect caused by changes of refractive index will affect absorbance measurements in a non-reproducible way.

To eliminate matrix interference, an assay protocol must be designed in such a way that its final step, monitoring of absorbance is carried out on homogenous reaction mixture, when reactions are at equilibria on still solution of uniform composition held in a flow cell.

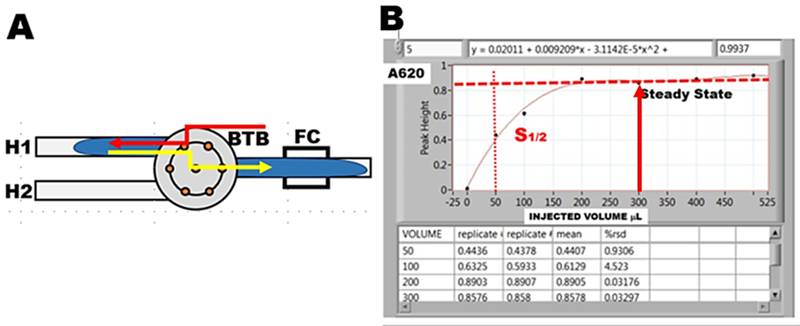

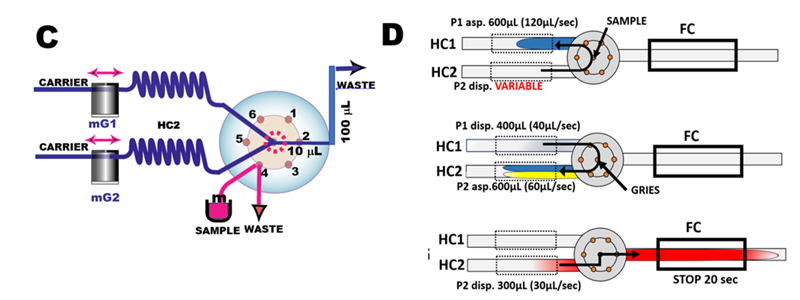

To eliminate concentration gradient, formed while sample zone travels to and through a flow cell, the volume of this flow path must be minimized, and the injected sample volume must be maximized until solution within entire length of the flow cell has a uniform composition. To find out when this condition is met, increasing volumes of a dye (bromothymol blue BTB, Amax 620nm) are injected into lab-on-valve manifold (A), furnished with a flow cell for absorbance measurement. By plotting the height of recorded peaks vs. injected volumes (B), an F-curve is obtained where at S ½ volume absorbance equals 50% of steady state value while at four S ½ volume absorbance reaches 96% of steady state. Therefore, when using this, lab-on valve manifold (C) where sample travels through 20 μL flow path into 100 μL 20cm long flow cell, the last step of flow protocol (D) must be designed to transport 300 μL of sample + reagents mixture into flow cell for absorbance monitoring.

The flow-batch protocol (D) for spectrophotometric single reagent assay is designed to generate homogenous mixture of sample with reagent. This is achieved during the second step of protocol, where local turbulence breaks laminar flow pattern (See movie clip in “Optimizing FI at continuous flow”).

Note that volumes and flow rates of merging streams in the second step of batch-flow protocol (D) are selected in such a way that sample and reagent zones exactly overlap. Further homogenization takes place when reaction mixture travels from holding coil 2 into flow cell.

Absorbance values are collected in the third step of the flow protocol at the end of stop flow period when chemical reaction reached equilibria and monitored solution is held still within the flow cell.

Feasibility of this method was verified by correlation of slopes of calibration lines generated by automated Single Standard Calibration method (SSC) (Section 3.2.5.) obtained with standard prepared in deionized water, sea water [1] and simulated sea water (3.5% NaCl) for determination of:

2. Research applications

Chemical reactions are described by variety of data which were obtained by batch technique at equilibrium conditions. In context of reagent based analytical techniques, stability constants, association constants, solubility, molar absorptivity (extinction coefficient) [3] and pH values are those that serve as a guide in optimizing conditions for any assay. Flow Injection programmed in batch mode can obtain these data automatically while using lesser reagent volumes than by manual batch technique. Examples of such approaches are:

References

[1] Hatta, M.; Ruzicka, J.; Measures, C.; Davis, M. Automated calibration by a single standard solution prepared in deionized water by flow programming eliminates the schlieren and salinity effects and is applied to the determination of phosphate in sea water of different salinities. Talanta 2023, 253, 124041.

[2] Mariko Hatta, Jaromir (Jarda) Ruzicka, Christopher I. Measures, Madeline Davis “Programmable flow injection in batch mode: Determination of nutrients in sea water by using a single, salinity independent calibration line, obtained with standards prepared in distilled water “Talanta 232 (2021) 122354.

[3] Ruzicka, J.; Marshall, G. D.; Measures, C. I.; Hatta, M., Flow injection programmed to function in batch mode is used to determine molar absorptivity and to investigate the phosphomolybdenum blue method. Talanta 2019, 201, 519-526.