3.1.2. Two reagents assay

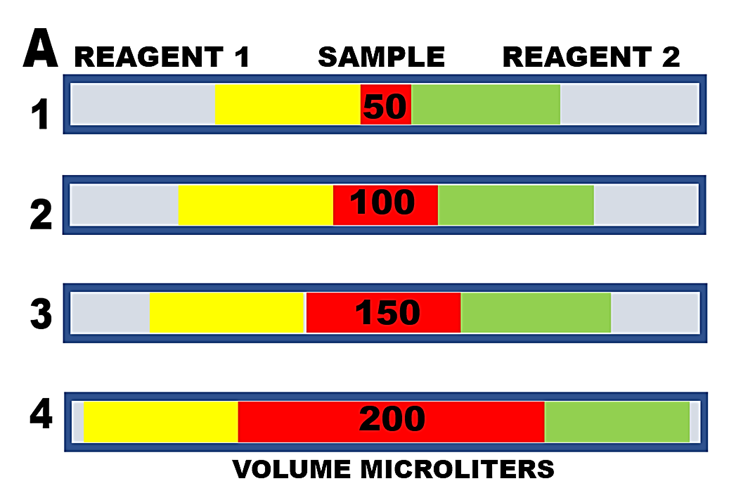

Sequencing sample zone between two reagent zones into “sandwich“ configuration (A) is used for automation of two reagents-based assays in Sequential Injection format. Note that in this configuration, as well as in sample/reagent sequence for single reagent SI, it is the axial dispersion of sample/reagent zones that forms reaction mixture. This flow geometry imposes a limit on volumes and number of components (three) that can be successfully mixed.

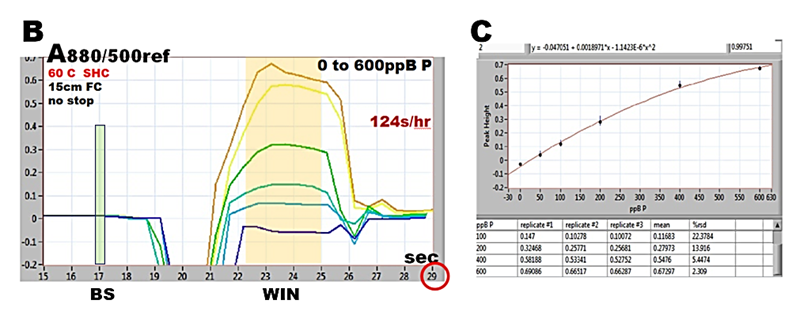

Let us examine limits of this approach on determination of phosphate, based on spectrophotometry of phosphomolybdenum blue, which is performed by sequencing sample between molybdate reagent and ascorbic acid, into thermostated (at 60 C) holding coil. In the next step the reaction mixture is transported by flow reversal through flow cell for absorbance monitoring (B). The maximum absorbance recorded within WIN interval correlated to baseline value BS, yields a calibration curve (C) which is nonlinear above 200 ppB P concentration.

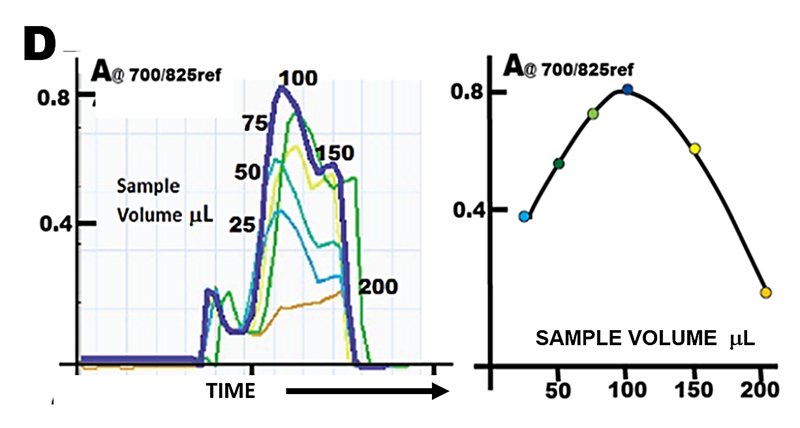

The inherent flaw of Sequential Injection method is due to low concentration of reagents within the center of sample zone. As sample volume increases from 50 µL to 200 µL the response becomes nonlinear followed by peak distortion and collapse. Sandwich based reagent assays in SI format, including phosphate and ammonia (D) follow the same pattern caused by increase of sample volume: loss of linearity, decrease in reproducibility and ultimately loss of response.

The inherent flaw of Sequential Injection method is due to low concentration of reagents within the center of sample zone. As sample volume increases from 50 µL to 200 µL the response becomes nonlinear followed by peak distortion and collapse. Sandwich based reagent assays in SI format, including phosphate and ammonia (D) follow the same pattern caused by increase of sample volume: loss of linearity, decrease in reproducibility and ultimately loss of response.

In spite of its limitations SIA method became widely used (over 1.200 references in Hansen’s Database) for automation of determination of a variety of analytes in laboratory, as well as in process control applications, because it offers:

In spite of its limitations SIA method became widely used (over 1.200 references in Hansen’s Database) for automation of determination of a variety of analytes in laboratory, as well as in process control applications, because it offers:

- Low reagent consumption and waste generation

- Reproducibility and reliability – due to syringe or milliGAT pump drive

- Versatility due to software control of assay protocol

- Flow programming that facilitates adjustment of incubation time and rapid washout of flow channel